Understanding Wood Warping: Causes, Effects, and Prevention

Wood Warping Demystified: Causes, Impacts, and How to Prevent It

Wood warping is a common challenge faced by woodworkers, builders, and restorers, especially when working with historic timber structures. It occurs when wood changes shape unevenly due to moisture fluctuations, stress, or environmental factors, leading to bent, twisted, or cupped boards and beams.

This article explores what causes wood warping, the different types of warp, why it matters for timber construction and restoration, and how to prevent or mitigate it to keep wood stable and beautiful.

What Causes Wood Warping?

Wood is a hygroscopic material, meaning it absorbs and releases moisture depending on the surrounding air's humidity levels. When wood dries, it shrinks; when it absorbs moisture, it expands. Warping happens when these changes are uneven across the wood piece.

Wood contains two types of water: free water inside the cell cavities and bound water within the cell walls. When wood dries below its

fiber saturation point (about 26% moisture content), the bound water starts to leave, causing shrinkage. Uneven drying or moisture absorption, such as one side drying faster than the other, creates internal stresses that distort the wood.

Other factors influencing warping include:

- Wood species: Different species have varying grain structures and densities that affect shrinkage rates.

- Grain orientation: Flat-sawn wood tends to warp more than quarter-sawn wood due to the alignment of growth rings.

- Environmental exposure: Direct sunlight, temperature swings, and airflow unevenness can accelerate warping.

- Season and handling: Even the timing of tree cutting and handling during drying can impact stability.

Types of Wood Warping

There are four main types of wood warp characterized by how the board bends or twists:

- Bow: A long, gentle curvature along the board's flat face, like a bow shape.

- Crook: A bend along the edge of a board resembling a curved sword shape.

- Cup: The edges of the board turn up while the center remains lower, creating a cupped appearance across the width.

- Twist: The board twists so opposite corners rotate in different directions, causing a spiraled distortion.

Why Wood Warping Matters for Timber Structures

Warping can affect both the structural integrity and aesthetic appeal of timber buildings or furniture. In structural timber:

- Warped beams or joists may not fit together properly, compromising load distribution.

- Twisted or bowed boards can make assembly difficult and cause gaps or uneven surfaces.

- Over time, warped wood is more prone to cracking, splitting, and further degradation.

In historic restoration, maintaining the original timber’s condition and appearance is vital. Warped wood can diminish the authenticity and longevity of these heritage structures.

Preventing Wood Warping: Best Practices

Though warping cannot be eliminated entirely, it can be minimized through careful handling, selection, and treatment:

- Proper drying: Kiln drying wood slowly and evenly to reach the desired moisture content reduces internal stresses. Monitoring moisture during drying is essential to prevent uneven moisture gradients.

- Acclimation: Before installation or use, wood should be acclimated to the environment where it will be placed, allowing moisture contents to balance gradually.

- Storage: Store lumber flat with spacers for air circulation and keep it away from direct sunlight or rapidly changing humidity.

- Choice of cut: Quarter-sawn boards are more stable and less prone to warping than flat-sawn boards. They are preferred for structural and fine woodworking applications.

- Environmental control: Maintaining stable indoor humidity and temperature in buildings preserves wood condition.

- Design considerations: When building or restoring, orient warped boards so the curve counters the expected loads or use methodical joinery that accommodates slight movements.

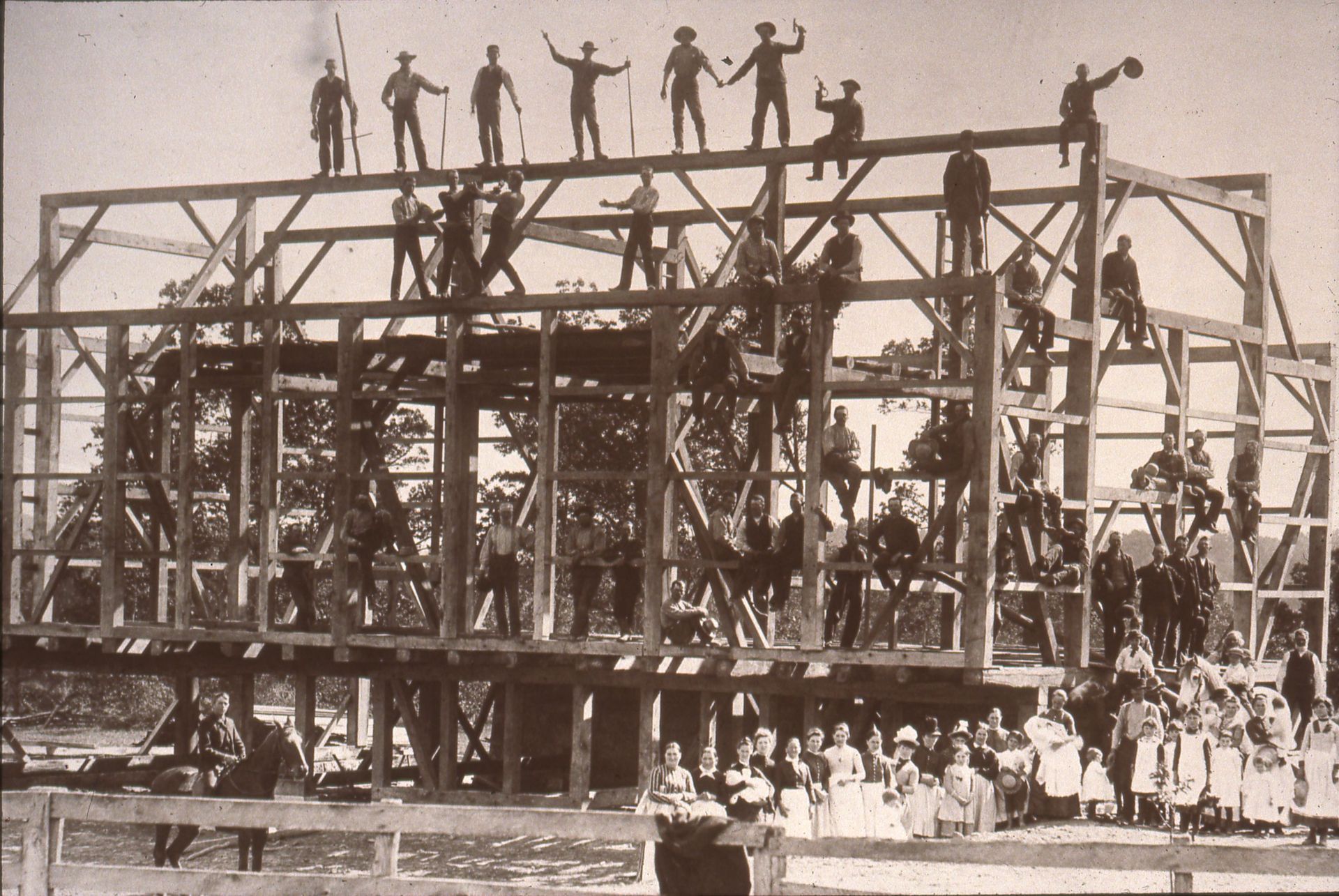

Bay & Bent’s Expertise in Historic Timber Frames

Bay & Bent specializes in sourcing the finest historic barn frames from across the country, disassembling, repairing, and preparing them with meticulous care. Our deep understanding of wood behavior, including wood warping, ensures each frame is stabilized through expert craftsmanship before being delivered and re-erected anywhere globally.

Learn more about our passion for preserving historic timber structures and our team at

Bay & Bent.

Conclusion

Wood warping is an unavoidable but manageable trait of working with timber. By understanding its causes and manifestations, and adopting prevention measures such as proper drying, acclimation, and storage, woodworkers and restorers can greatly reduce warp’s impact on their projects.

With expert care like that practiced by Bay & Bent, historic frames can be preserved with integrity, allowing the beauty and character of timeless timber to shine through in new homes and projects.

This comprehensive knowledge of wood warping bridges the gap between tradition and modern performance, keeping heritage structures stable and beautiful for generations to come.